About Bizwheel

The main component of a healthy environment for self esteem is that it needs be nurturing. It should provide unconditional warmth.

All Tools are manufactured in the United States of America

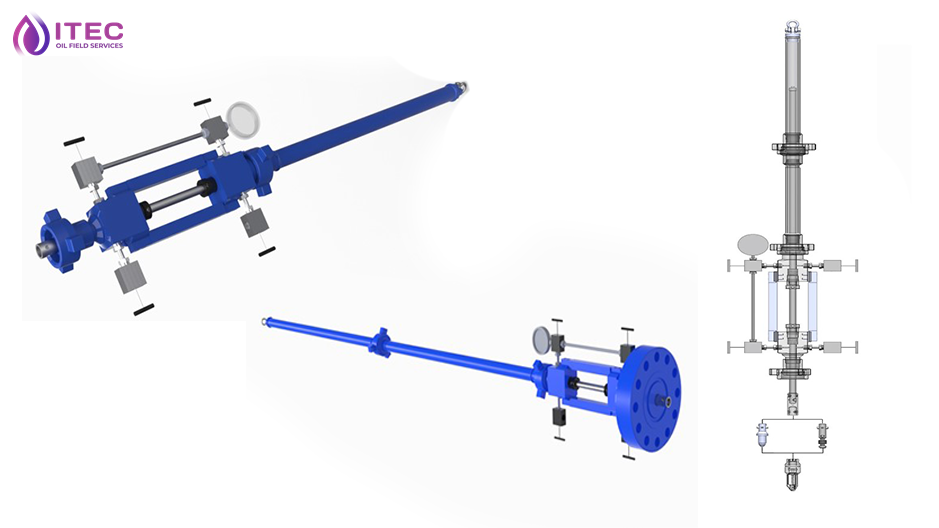

BPV manual Lubricator safely facilitates BPV & TWCH installation into wellhead tubing hanger to isolate and contain wellbore pressure for wellhead and tree intervention and repairs operations.

The Lubricator operation avoid costly workover activities and slickline operations. The straightforward operation of lubricators makes it much safer to run BPV than slickline units.

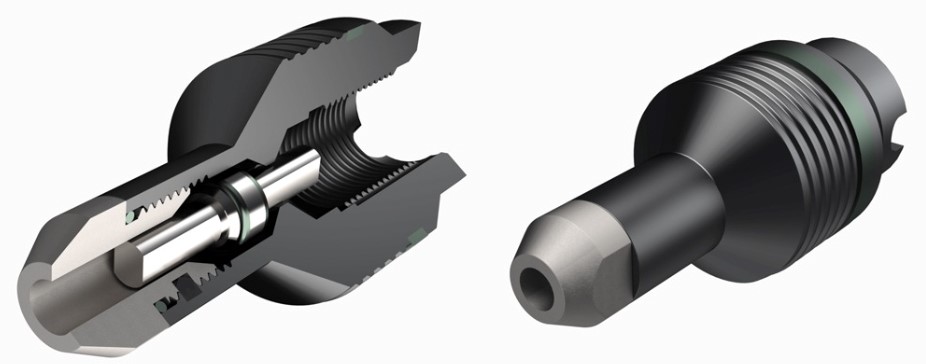

‘H’ BPV is a type of check valve installed in Tubing Hangers to isolate well production. Type H back pressure valves, or Type H BPV, are designed to hold pressure from below and enable fluids to be pumped from above as needed for well-control.

H’ BPV designed for

‘H’ Back Pressure Valves (BPV) are used to safely seal tubing pressure up to 20,000 PSI during tree installation, remove the blowout preventer, and circulation fluid back down the tubing.

If the tree above the tubing is to be pressure tested, the ‘H’ Two-Way Check Valves (TWCV) is landed in the tubing hanger to allow testing of pressure up to 20,000 PSI.

Shallow threads on the ‘H’ Back Pressure and Two-Way Check Valves provide strength for extreme pressure with minimum reduction in bore size, providing a passage of API drifts for the size of the tubing suspended.

‘H’ BPV and TWCV Benefits:

‘H’ TWCV was designed to fit the same profile in the tubing hanger as BPV. Two-Way Check Valve holds pressure from both directions while allowing balance when required and is used to test the tree and BOP assembly.

‘H’ TWCV is available:

‘H’ TWCV designed for